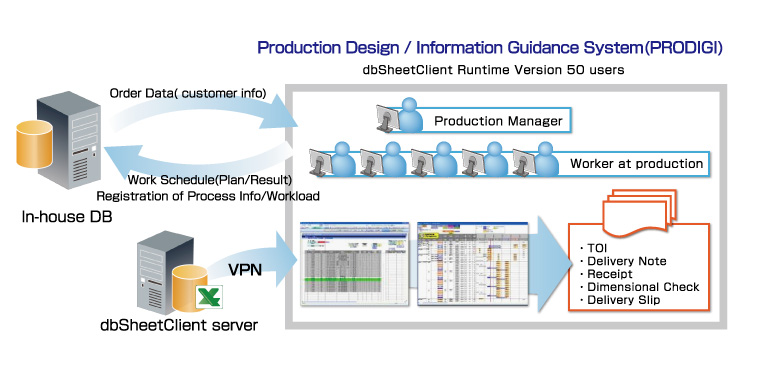

System configuration Chart

Production Design / Information Guidance System

System scale

- Number of registered screens: 22

- Number of forms: 5

- Development started: January 2010

- Actual performance started: July 2007

System overview

- Production Design/ Information Guidance System

- The manufacturing dept. of the prototype business introduced dbSheetClient and built the new Production Design/ Information Guidance System (hereinafter referred to as the New System) under its own initiative, and established the formation of workflows to achieve the delivery of high quality prototype models to customers in a short time. The outline of the new system is as follows:

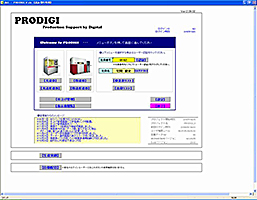

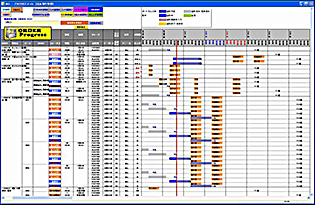

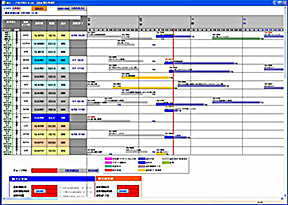

- 1. Production schedule management (Title: PRODIGI-V)

- Equipped with a function for the production planning and delivery control in one window, based on the order information. The Managers of each stage of the production process register their planning and the work personnel register how many work-hour have actually been taken. Planning and actual data can be grasped at once and became manageable with this system. Also, production information, technical information, and work support tools are available.

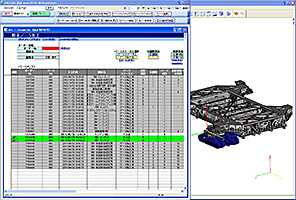

- Capture from PRODIGI-V (1)

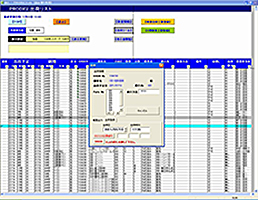

- Capture from PRODIGI-V (2)

- 2. Production technology information management (Title: PRODIGI - Design)

- Based on the order information and 3D data received from customers, an engineer will create processing data and technological information for the quality requirement. Based on this information, production information, such as with which forming machine (processing machine) and from when and how it is to be processed, is registered. The forming schedule and production information are to be checked in the post processing (forming, finishing, inspection, shipping) through PRODIGI-V, and especially the technological information about the quality requirement will be transmitted to all the post processings through PRODIGI-V

- Capture of PRODIGI-Design

- Capture of technical information

Purpose of the system development and examination of the development method

Due to a changing trial production market of diversified products, as well as the changes in specifications after orders are received (typical of the trial production business), our Manufacturing Department for Prototype Business faced an urgent necessity to make a major improvement to the conventional production management and business support system to cope with these demands in a shorter period. To do so, the following were conditions for selecting a new system.

• The system should allow for operation and improvements under the initiative of the production dept.

• The system should allow for rich Excel resources for efficiency improvement which were created by using/reusing MS Excel VBA.

We compared the existing systems, dbSheetClient, which we eventually decided to introduce this time, and two other systems from different companies. Points for the comparative examination were the following four issues:

1) Development requirement : Ease of implementation

2) Function requirement : Flexibility to cope with the demands for functional expansion

3) Performance requirement : Capacity of the system itself

4) Maintenance : Ease of maintenance

Reasons why we adopted dbSheetClient and how the development took place

We conducted a comparative examination of the existing system and others offered by three companies for about three months starting in September 2009, and decided to install Newcom's dbSheetClient. On the assumption that system development and its maintenance will be conducted by in-house personnel, it is indispensable that the system be capable to address requests for improvement from the workplace promptly and have feasible maintenance capability to realize stable operability; therefore, we reached the conclusion that dbSheetClient is best suited for our needs. After this screening, we purchased dbSheetClient in December 2009, and the development began in January. 2010

The development workloads were assigned as follows: 0.5 man-months for DB design, 1.5 man-months for VBA coding of the screen drawing and 1 man-month for dbSheetClient building, and the development. They were carried out in three stages (Stage1: Beginning of April, 2010), (Stage 2: Beginning of June, 2010), (Stage 3: Beginning of July, 2010) with each personnel assigned continuing to work on their previous jobs beside the development. Actually, operational tests started through the release at the Stage 2, and we started full operation from July with the new system. In Stage 1, the Gantt chart and production management function, which the previous system did not have, were released. In Stage 2, windows and forms for each process and its function (man-hour registration, etc.) replaced those of the previous. Version 3 is the refactoring version of Version 2, and by conducting the refactoring of the definition files in VBA and dbSheetClient, the operation response and maintenance were improved.

About the development and the effect from installation

When we were deciding to make a system with dbSheetClient by using the existing Excel resources, we tried to make the most of the innate function of dbSheetClient. The product (dbSheetClient) has parts called Task Types, and by combining them, we achieved quite a complex logic assembly. However, not every function we sought was expressed by Task Types only. For the parts still missing, we made good use of Excel VBA. We also received technical assistance from Newcom during development, and to our satisfaction, we could build the system as we planned. Initially, we thought of combining the existing database and Excel by using DAO (Data Access Object), but dbSheetClient was, after all, the best choice for its ease of system building and maintenance. This is because it is "easy to understand." Since it is the field workers who built the system, not the system engineers, the approach of reading data from the database and writing it into Excel is very visual and easy to understand for them, because the process of connecting to database and writing data into forms in Excel (by VBA) can be separated in a practical manner. Any errors from malfunctions can be identified promptly and the verification process has been shortened. Moreover, because it is easy to change the user interface, it is easy to respond to the demands from the field, and we enabled the system to be used by and accustomed to field personnel in a short period. In retrospect, without dbSheetClient, it would have been impossible to build a substantial system to involve all aspects of the production activities and to replace the previous system with the new system in such a short period.

There are two major effects of introducing the new system.

The first effect is that the workload for scheduling is reduced, which enabled us to respond with delivery dates for the change of specification from our customers in a short time. In the new system, visualization of information with the most easy-to-understand perspective for grasping the situation at each process of production, from receiving orders to shipping, has been achieved. For example, in the production scheduling which needs to see all the orders, planned workloads of the whole process and state of progress can be grasped by Gantt charts for each order. In the molding process, the operational status of the molding machine and future schedule are grasped through the Gantt chart for each molding machine, and at the final stage, the resources and the stage of progress of each finisher is verified. At the shipping stage, the items to be shipped on the day are listed for display with each shipment as a unit, and the progress status for scheduled shipping may be grasped. Not only the progress status in the factory but also the production schedule is visualized. By installing an interface to register and rearrange the schedule, the response of the delivery due by the sales dept. and the arrangement of the manufacturing to the requirement changes by customers (increase/decrease of the production volume, change in material, shape., etc.) was shortened.

- The scheduling of whole process of each order (Gantt chart)

- Operation status of all molding machines (Gantt chart)

The second is that the required specification changes to the system are dealt with in a short time. For instance, tabulation, analysis, and reporting of the production result are conducted automatically, but the indexes for each process or for each stage of the working site improvement are changed. Since the previous system was made with Java, it required some man-hours to deal with even a small change, but since the new system is made in Excel and VBA, it can be handled in a short time. We became capable of delivering an effective production index in a timely manner to the production workplace, which stimulates the motivation for workers to make improvements.

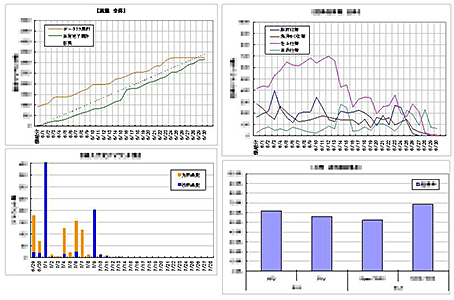

- Various types of graphs according to result or goal